DISAMATIC

DISAMATIC is an automatic production line used for fast manufacturing of sand molds for sand casting. This process is commonly used to mass manufacture of metal castings for the automotive and machine industry.

History

In 1957, Vagn Aage Jeppesen - professor at the Danish Technical University claimed a patent for a device producing flaskless molds of sand mixtures with vertical parting lines for casting metal parts. In 1960, Danish company Dansk Industri Syndikat A/S (DISA) acquired the patent and started working on its implementation.

In 1962, a half scale prototype of a sand molding machine with flaskless and vertically parted molds under the name of DISAMATIC was ready to be disclosed. During the International Foundry Trade Fair (GIFA) in 1962 in Düsseldorf the scale model was demonstrated on DISA's stand. This resulted in sales of two first DISAMATICs to European foundries. The first automatic DISAMATIC molding lines could produce up to 240 complete sand molds per hour.

Process

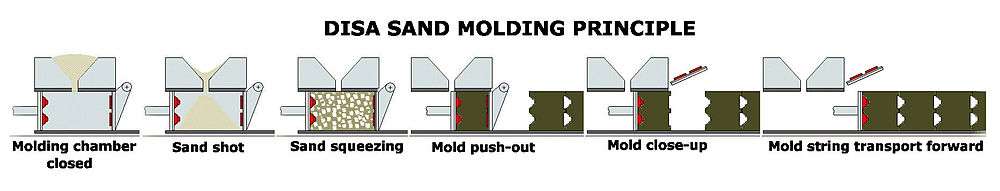

DISAMATIC consists of a molding machine and mold transporting conveyor. A molding sand mixture, usually green sand or bentonite, is blown into a rectangular steel chamber using compressed air. The molding sand is then squeezed against two patterns, which are on the two ends of the chamber. After squeezing, one of the chamber plates swings open and the opposite plate pushes the finished mold onto a conveyor. Finally, any cores are automatically set into the mold cavity while the next mold is being prepared. The cycle repeats until a chain of finished molds butt up to each other on the conveyor.

The molds are then filled with molten metal and placed on a cooling conveyor, which moves at the same pace as the fabrication conveyor. At the end of the conveyor the solidified castings are separated from the molds and processed further, while the sand is directed to the sand preparation plant for reconditioning and reuse in the next cycles of the DISAMATIC molding process.

Advantages

The DISAMATIC sand molding process has several advantages comparing to other molding processes. It does not use flasks, which avoids a need of their transporting, storing and maintaining. It is fully automatic and requires only one monitoring operator, which reduces labor costs. Molding sand consumption can be minimized due to variable mold thickness that can be adjusted to the necessary minimum.

A modern DISAMATIC molding line can mold at the rate of 550 sand molds per hour (one complete mold in 6.5 seconds). Maximum mis-match of two halves of the castings does not exceed 0.1 mm (0.0039 in). Total uptime exceeds 98%. Possible mold sizes range from 400 x 500 to 850 x 1200 millimeters. A DISAMATIC line can be completed with automatic casting and sand cooling drums, robotized devices for extracting castings from the molds and automatic casting cleaning and abrasive blasting machines placed inline. In such automatic production lines there is no need of any human manual labor until the castings are completely finished and ready for dispatch.