Lombe's Mill

|

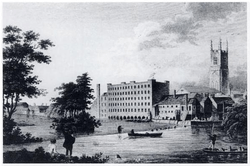

Lombe's Mill, viewed across the River Derwent, 18th century. | |

Location within Derbyshire | |

| Silk | |

|---|---|

| Alternative names | Italian Works |

| Structural system | brick |

| Owner | John Lombe |

| Coordinates | 52°55′32″N 1°28′32″W / 52.9256°N 1.4755°W |

| Construction | |

| Built | 1721 |

| Height | 17m |

| Floor count | 5 |

| Other dimensions | 33.5m x 12m |

| Water Power | |

| Diameter / width of water wheel | 7m / |

| Other Equipment |

|

Lombe's Mill was the first successful silk throwing mill in England. It was built on an island on the River Derwent in Derby. It was built after John Lombe visited Piedmont in 1717 and returned to England with details of the Italian silk throwing machines – the filatoio and the torcitoio – and some Italian craftsmen.[1] The architect was George Sorocold.

Location

Lombe's Mill was built next to Thomas Cotchett's 1704 mill on the west bank of the River Derwent in Derby. At this point a weir had been constructed across the river, and the mill was built on an island downstream which separated the river from the tail race of three corn mills. The tail race was also called a fleam or a leat. Derby was a key location as the river had a fast flow, and it was here that it was crossed by the London to Carlisle road

History

Lombe's Mill was the first successful silk throwing mill in England and probably the first fully mechanised factory in the world.[2] Thomas Cotchett's mill, built in Derby in 1704, was a failure. John Lombe had visited the successful silk throwing mill in Piedmont in 1716, an early example of industrial espionage. He returned to Derby with the necessary knowledge and a group of Italians. He designed the mill, and with his half-brother Thomas Lombe (born 1685) instructed George Sorocold to build it and fit it with the new machines. It was built to the south of Cotchett's Mill.

Thomas Lombe was given a 14-year patent to protect the design of the throwing machines. The King of Sardinia reacted badly to the commercial challenge, placing an embargo on the export of raw silk. It is speculated that he was responsible for John Lombe's mysterious death, six years later, in 1722. John's elder brother, Thomas, took over the business. When the patents lapsed in 1732, other mills were built in Stockport and Macclesfield. An unpowered doubling shop was built to the north of the powered Italian works some time before 1739. The mill was sold to Thomas Wilson in 1739. An inventory was taken of the doubling shop, which still exists.[1]

Italian works

A description of the mill, dating from between 1739 and 1753, says: "The original Italian works of five storeys high housed 26 Italian winding engines that spun the raw silk on each of the upper three floors whilst the lower two storeys contained eight spinning mills producing basic thread and four twist mills."[3] Little of the original mill remains. It was built of brick, in flemish bond, and was 33.5m long and 12m wide. It was built on a series of stone arches that allowed the waters of the River Derwent to flow through. The mill was 17m high, topped by a shallow pitched roof. The throwing machines were two storeys high and pierced the first floor. The winding machines were situated on the top three floors. All the machines were powered by Sorocold's 7 metres diameter, 2-metre wide external undershot waterwheel. Its axle entered the mill through a navel hole at first floor level. It drove a 0.45-metre square vertical shaft that drove a line shaft that ran the length of the mill. The torcitoios and filatoios took their power from the shaft. The vertical shaft was extended beyond the second floor by an iron gudgeon to another vertical shaft that reached the top 3 floors to drive the winding machines. The mill was heated to process the silk, and this was explained in the 1718 patent. It was reported that Lombe used a fire engine (steam engine) to pump hot air round the mill in 1732. The stair column was 19.5m high. Its layout is not known, and there is no information on how bales were hoisted between the floors.[1]

Doubling shop

The main range was three storeys high, 42.4m by 5.5m. Each floor was used for doubling, and there were 306 doubling machines.[1]

The silk throwing process

Silk is a naturally produced fibre obtained from many species of the silk moth. In 1700 the favoured silk was produced by a moth (Bombyx mori), that spun a cocoon to protect the larvae. The larvae fed on mulberry leaves grown in Italy. Silk fibres from the Bombyx mori silkworm have a triangular cross section with rounded corners, 5–10 μm wide. The silk is a protein, fibroin, that was cemented in place by the use of gum, another protein, sericin. The cocoons were harvested and placed in troughs of hot water to dissolve the gum and allowed the single thread to be wound into a skein. The skeins were placed into bales and taken to the mill for processing. Three sorts of yarn could be produced: no-twist which was suitable for weft, tram that had received a slight twist making it easier to handle, and organizine which had a greater twist and was suitable for use as warp.[4] Reeling is the industrial process where silk that has been wound into skeins, is cleaned, receives a twist and is wound onto bobbins. Silk throwing is the process where the thread from the bobbins is twisted again to form tram and or organzine. The yarn is twisted together into threads, in a process known as doubling. Colloquially silk throwing can be used to refer to the whole process: reeling, throwing and doubling.[1]

In 1700, Italians were the most technologically advanced throwsters in Europe and had developed two machines capable of winding the silk onto bobbins while putting a twist in the thread. They called the throwing machine, a filatoio, and the doubler, a torcitoio. There is an illustration of a circular handpowered throwing machine drawn in 1487 with 32 spindles. The first evidence of an externally powered filatoio comes from the thirteenth century, and the earliest illustration from around 1500.[1] Filatorios and torcitoios contained parallel circular frames that revolved round each other on a central axis. The speed of the relative rotation determined the twist. Silk would only co-operate in the process if the temperature and humidity were high, in Italy the temperature was elevated by sunlight but in Derby the mill had to be heated, and the heat evenly distributed.[1]

Today

The mill passed through several owners and has been rebuilt several times, but the modified structure is extant and has been restored to house the Derby Silk Mill. There is a Bas relief sculpture of John Lombe at the nearby Exeter Bridge.

See also

| Wikimedia Commons has media related to Derby Industrial Museum – Silk Mill. |

References

- Notes

- Bibliography

- Calladine, Anthony (1993). "Lombe's Mill: An Exercise in reconstruction". Industrial Archaeology Review. Maney Publishing. XVI (1). ISSN 0309-0728.

- Darley, Gillian (2003). Factory (Objekt). London: Reaktion Books. ISBN 1-86189-155-5.

- Rayner, Hollins (1903). Silk throwing and waste silk spinning. Scott, Greenwood, Van Nostrand.

- Warner, Frank (1921). "18". The silk industry of the United Kingdom. Its origin and development. London: Dranes. pp. 198–211. OCLC 2303073. Retrieved 12 June 2011.

External links

- "The Silk Mill". Derby City Council. Retrieved 26 May 2010.