Mimics

|

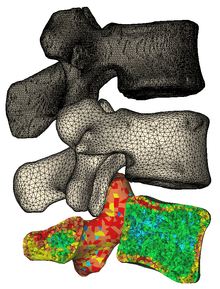

3D surface models created in Mimics from CT | |

| Developer(s) | Materialise NV |

|---|---|

| Stable release |

19.0

/ June 2016 |

| Operating system | Windows |

| Platform | 32/64bit |

| Website | Mimics' Homepage |

Materialise Mimics is an image processing software for 3D design and modeling, developed by Materialise NV,[1] a Belgian company specialized in additive manufacturing software and technology for medical, dental and additive manufacturing industries. Materialise Mimics is used to create 3D surface models from stacks of 2D image data. These 3D models can then be used for a variety of engineering applications. Mimics is an acronym for Materialise Interactive Medical Image Control System. It is developed in an ISO environment with CE and FDA 510k premarket clearance. Materialise Mimics is commercially available as part of the Materialise Mimics Innovation Suite, which also contains 3-matic, a design and meshing software for anatomical data. The current version is 19.0, it supports Windows 10, Windows 7, Vista and XP in both x32 and x64.

Process

Materialise Mimics calculates surface 3D models from stacked image data such as Computed Tomography (CT), Micro CT, Magnetic Resonance Imaging (MRI), Confocal Microscopy, X-ray and Ultrasound, through image segmentation. The ROI, selected in the segmentation process is converted to a 3D surface model using an adapted marching cubes algorithm that takes the partial volume effect into account, leading to very accurate 3D models.[2][3] The 3D files are represented in the STL format.

Most common input format is DICOM, but other image formats such as: TIFF, JPEG, BMP and Raw are also supported.

Output file formats differ, depending on the subsequent application: common 3D output formats include STL, VRML, PLY and DXF. The 3D files can also be optimized for FEA or CFD and can therefore be exported to Abaqus in INP format, to Ansys in INP, CDB and MSH format, to Nastran in OUT, NAS and BDF format, and to Comsol in MPHTXT format. To continue with Computer-aided design, the files can be exported in IGES format or as Point cloud.

Industries

Mimics has been adopted by biomedical engineers and device manufacturers for R&D purposes in various medical industries:

- Cardiovascular

- Craniomaxillofacial

- Orthopedic

- Pulmonology

These industries use patient-specific 3D data to improve their implants and devices or to get a better understanding of biomechanical processes. Also non-medical industries like materials science use Mimics in image-based R&D.

Applications

Materialise Mimics is a platform to bridge stacked image data to a variety of different medical engineering applications:

- 3D measurements and analyses

- Computer Aided Design: 3-matic, SolidWorks, Pro/E...etc.

- Computational Fluid Dynamics: FLUENT, CFX,...etc.

- Customized implant design

- Finite Element Analysis: ABAQUS, ANSYS,...etc.

- Rapid Prototyping: EOS, Stratasys, 3D Systems, ZCorp, Dimension, Objet, ... etc.

- Surgical simulation

Gallery

- Image import from CT (DICOM)

- Image segmentation

3D model

3D model

See also

References

- ↑ materialise.com

- ↑ Gelaude F, Vander Sloten J, Lauwers B. Accuracy assessment of CT-based outer surface meshes, Computer Aided Surgery 2008, 13(4), p188-199.

- ↑ Jamali AA et al. Linear and angular measurements of computer-generated models: are they accurate, valid and reliable? Computer Aided Surgery 2007, 12(5), p278-285.