Tonedale Mills

| Tonedale Mills | |

|---|---|

Pictured in 2010 | |

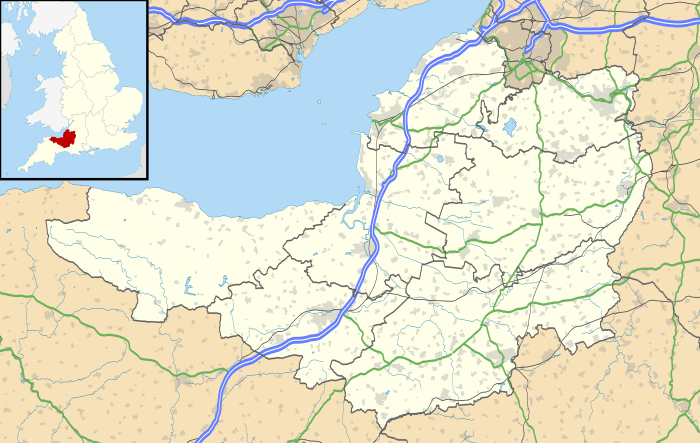

Location in Somerset | |

| General information | |

| Location | Wellington, Somerset |

| Coordinates | 50°59′05″N 3°14′40″W / 50.984828°N 3.244368°W |

| Opened | 1790 |

Tonedale Mills, including Tone Mills, was a large wool factory in Wellington, Somerset that was the largest woollen mill in South West England. Owned by Fox Brothers, it was most famous for the production of "Taunton serge", and later the khaki dye used by the British Army. The mill was established in the middle of the eighteenth century, and thrived during the industrial revolution. At its peak, around 6,500 metres (21,300 ft) of material was produced at the factory each day. The cheap cost of producing fabric in third-world countries contributed to the factory mostly closing during the 1980s, but small-scale production continues on part of the site.

History

During the reign of Queen Elizabeth I, the Were family of Wellington began producing serge as a cottage industry. In the early 1700s, Edward Fox married Hannah Were, and soon took over the trade.[1] The wool industry thrived in areas used for sheep farming, like Somerset, and Taunton serge was particularly popular due to its balance between being light-weight and yet sufficiently thick.[2] The Were family established Tone Mills in 1754, and over the next seventeen years, the family's assets quadrupled as the industry thrived.[1] Thomas Fox, after learning the trade in Germany and the Netherlands for three years,[1] entered the business as a partner, and formally founded the company as Fox Brothers in 1772.<ref name="foxhist"/ The technological breakthroughs of the late 18th century revolutionised textile manufacture,[3] In the 1790s, Fox Brothers purchased a complex of buildings in Tonedale known variously as the "Old Town Mills" or the "Old Flour Mills" to centralise their processes.[4] This move facilitated an increase in both quality and quantity, while cutting costs as other production was brought in-house; basket weaving, joinery, book binding and metalworking was all carried out on the site.[2]

.jpg)

The site is notable for having remains of each phase of power generation: water, steam and electricity,[5] as when steam power was introduced, Fox Brothers opted to retain their water management system as it might prove useful. The site was continually growing through the nineteenth century, and at its peak employed around 3,600 people around Wellington, and produced 6,500 metres (21,300 ft) of material each day.[1] At the Tonedale complex, dyers working for Fox Brothers developed a khaki dye which was used by the British soldiers in the Second Boer War.[6] The complex was the largest woollen mill in South West England, and was rare in integrating ancillary processes on the same site. The mill continued to produce cloth on a large scale until it downsized in the 1980s. Most of the site is now abandoned, though parts are still used for small-scale production, and others have been sold off and converted into a small industrial estate.[4] In 2009, Deborah Meaden and Douglas Cordeaux invested in Fox Brothers, allowing production to continue at Tonedale, after the company had been in danger of falling into bankruptcy.[7]

Mill complex

Tone Mills

Due to the acquisition of the old flour mills, which became the main Tonedale Mills site, the older Tone Mills, a few hundred metres further north, became the cloth finishing works. Sitting on the banks of the River Tone, the mills originally used water wheels on the river for power generation, the housing for which are still in place. Later with the introduction of steam and then electric power, the water was used as part of the cloth finishing process, and was managed more carefully with the introduction of a reservoir and sluice gates. Within the reservoir, the water was treated before its use. The finishing works and dye factory were both on this site. The former had a boiler house attached, while the latter had an engine house added.[8]

Tonedale Mills

.jpg)

While the Tone Mills site was able to use water wheels on the River Tone for power generation, Tonedale Mills initially used smaller watercourses, Westford Brook and Rockwell Green Stream. In order to ensure that they had a constant supply of water, and that it was used as efficiently as possible, Thomas Fox had water basins excavated between 1801 and 1803, establishing a series of waterways, weirs and sluices to manage the water supply.[1] The original timber mill burned down in 1821, and was replaced by a brick mill, which remains today. The large site features a number of mills, warehouses, workshops and engine houses. Like the north site, evidence of water wheels as well as steam and electric power generation remains. The complex features factories for the preparation of the wool, including a combing shed and a wool cleaning complex.[5][9]

Regeneration

Plans to convert some of the site into housing were abandoned in 2008, during the global financial crisis, due to low levels of interest.[10] Development on the site was later supported by The Prince's Regeneration Trust,[11] and the site was listed on the Heritage at Risk register in 2010,[12] while the Tone Mills site was identified in 2014 as being among the top ten Heritage at Risk "priority" sites in the South West.[13] Most of the site has been grade II* listed, granting it a level of preservation by English Heritage, though the organisation accept that "comprehensive restoration and reuse would not prove commercially viable" due to the size and state of disrepair of the site.[14]

References

- 1 2 3 4 5 "Wellington Basins Heritage Trail" (PDF). Taunton Deane Borough Council. December 2006. Retrieved 20 July 2015.

- 1 2 "History". Fox Brothers & Co Ltd. Retrieved 16 July 2015.

- ↑ "The Industrial Revolution and the changing face of Britain". British Museum. Retrieved 16 July 2015.

- 1 2 "Somerset Historic Environment Record: Tonedale Mills, Tonedale, Wellington". Somerset County Council. 1986. Retrieved 16 July 2015.

- 1 2 "Tonedale Mills (East complex)". National Heritage List for England. Historic England. Retrieved 20 July 2015.

- ↑ Clark, Nick (8 October 2014). "Khaki factory and WW1 crane on list of 10 most at-risk buildings". The Independent. London: Independent Print Limited. Retrieved 20 July 2015.

- ↑ West, Karl (27 May 2012). "Dragon breathes fire into fabric". The Sunday Times. London: News UK. Retrieved 20 July 2015. (subscription required (help)).

- ↑ "Cloth finishing works at Tone Mills north range including dyehouse and reservoirs". National Heritage List for England. Historic England. Retrieved 20 July 2015.

- ↑ "Tonedale Mills (West complex)". National Heritage List for England. Historic England. Retrieved 20 July 2015.

- ↑ "Credit crunch hits homes development at historic mill site". Bristol Post. 29 July 2008. Retrieved 20 July 2015.

- ↑ "Tone Mill". Integral Engineering Design. Retrieved 20 July 2015.

- ↑ "Wellington mills 'at risk' say English Heritage". Somerset County Gazette. 14 July 2010. Retrieved 20 July 2015.

- ↑ "Heritage at Risk Priority Sites 2014" (PDF). English Heritage. 2014. p. 109. Retrieved 20 July 2015.

- ↑ "Tone Mill planning permission" (PDF). Taunton Deane Borough Council. Retrieved 20 July 2015.

| Wikimedia Commons has media related to Tonedale Mills. |