Vermidigester

A vermidigester (also called wormdigester) is an aerobic reactor where vermicomposting occurs. It can be addapted to all types of vermicomposting as domestic vermicomposting, urban vermicomposting, farm vermicomposting and agroindustrial vermicomposting.

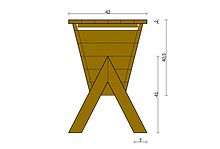

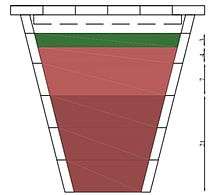

The system is constructed according to environmental engineering principles and procedures. One particular characteristic is that the top surface area is normally higher than the bottom surface area, as this increases pressure in the bottom and an increase in vermicompost release. However, other models cold not have this geometry.

Definition and basic principles

In all vermidigesters, the organic wastes are treated in treatment compartments. Consonant their typology, the treatment compartments may have a static configuration or a dynamic configuration. The great majority of vermidigesters have static compartments, as the dynamic compartments are fundamentally characteristic of the systems used in urban small scale vermicomposting. In this particular case, the systems are called vermicomposters, and vertical vermiculture systems, consisting these ones by stackable vertical boxes.

Relatively to the systems with syatic compartments, these may to be divided in compartment with a semipyramid configuration and compartments with uniform configuration, being the section for the deposition of the vermicompost open or closed. In the static configuration, the different wastes streams are treated in a single compartment, as this is subdivided by modules, being the vermicompost separated from the earthworms after deposition into a specific and independent compartment. In contrary, the systems with dynamic configuration, earthworms are separated from the vermicompost, using 3 to 5 vertical stackble compartments.

Process

The vermicomposting process that occurs in vermidigesters in slightly different when compared with traditional beds or conventional wormeries. The structure increases pressure inside the wall but also in the bottom. In result, the vermicompost produced over the process will fall more easily and more often when compared with traditional and conventional vermicomposting process. The entirely process is characterized as a vertical process, when earthworms work in the upper centimeters of materials. Pressure inside in the walls of the vermidigester is created since the vermicompost ans wastes in decomposition work like a fluid. In this case, since each material has a proper bulk density, each material will develop a proper pressure. Total pressure inside the vermidigester is dependend of the depth of each level.

Types

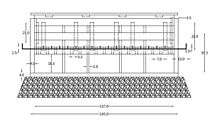

Vermidigesters should all have a lid, preventing the entry of natural or artificial light, and also rainwater. The bottom of the treatment section of a vermidigester consists of bars with 3 and 20 mm thick, with 30 to 100 mm space between each one. Other alternative to the previous bars is to apply a mesh with square ir circular holes with 8 to 12 mm gap. Several boxes are placed in the bottom of the system for the deposition of the vermicompost under the bars/mesh or, alternatively, it should be deposited in an appropriate section or waterproofed soil. Some systems may have a leachate holding compartment under the vermicompost compartiment.

Sizing and Design

Vermidigesters are sized according to the organic waste production per person per unit of time. Is well known that Eisenia fetida and Eisenia andrei earthworms ingest per day half of their own weight per day.[1][2] Each person produces near 500 g day-1 of organic food waste. On a typical household family of 4 persons, this should be a total waste production of near 2.0 kg day-1. Besides, an ideal treatment capacity is 2.5 kg m-2.day. According to this:

Earthworm density = treatment capacity * 2

Surface area required = organic waste production/treatment capacity

Mass of eaethworms required = Earthworm density * surface area required

Daily total vermicompost produced = organic waste production * 0.6

Maintenance

Vermicompost, as worm castings, will fall to the bottom of the system, by gravity of using mechanical processes. In general, domestic vermidigesters, doesn't require special mechanical processes since the organic loading of waste is not higher than 1-2 kg day-1. However, when the organic waste production increases - on farms, gardens of bigher families, a mechanic process should be installed in the vermidigester. This is particular important since 60% of the organic waste ingested by an earthwrorm is converted into wormcasts. [3][4]

See also

References

- ↑ LOURENÇO, N.(2010). Vermicompostagem, Gestão de Resíduos Orgânicos – Princípios, Processos e Aplicações. ISBN 9789899685512 FUTURAMB, 1.ª Ed. 404 pp.)

- ↑ LOURENÇO, N. (2014). Manual de Vermicompostagem e Vermicultura para a Agricultura Orgânica. ISBN 9789897230479. Publindústria, 1.ª Ed. 260 pp)

- ↑ LOURENÇO, N.(2010). Vermicompostagem, Gestão de Resíduos Orgânicos – Princípios, Processos e Aplicações. ISBN 9789899685512 FUTURAMB, 1.ª Ed. 404 pp.)

- ↑ LOURENÇO, N. (2014). Manual de Vermicompostagem e Vermicultura para a Agricultura Orgânica. ISBN 9789897230479. Publindústria, 1.ª Ed. 260 pp.)