Vermifilter

A vermifilter (also called biological filter with earthworms) is an aerobic treatment system that provides wastewater treatment by vermifiltration. In this biological reactor, is possible to made primary, secondary and tertiary treatment of influent blackwater and influent greywater, mainly at domestic scale for on-site treatment of domestic wastewater. However, vermifilters are used also for urban/municipal wastewater and agroindustrial wastewater.

Definition and basic principles

In the vermifilter, several reactions occur, being the organic matter removal and the pathogen destruction the most important ones. In fact, depending of several specific conditions, a vermifilter could have removal efficiencies for Biochemical Oxygen Demand (BOD5) more than 90%, Chemical Oxygem Demand (COD) more than 85%, Total Suspended Solids (TSS) more than 98% and NH4+ more than 75%. In specific conditions, is possible to achieve an elimination of faecal coliforms until 2.0 Log10 of Most Probable Number (MPN) per 100 mL−1.[1]

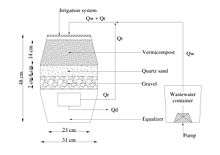

A typical vermifilter has three different sections: a organic filter - normally sawdust, and were the earthworms live; the inorganic or inert filter - constituted by a layer of gravel and a layer of sand; and the equalizer - where the treated effluent is discharged and recirculated to the top of the filter. The organic filter is also called filter packing where solids are acumulated on the surface while the liquid fraction drains through the medium, being discharged and normally reused for irrigation. Wastewater is applied on the top of the filter packing by droping or by sprinklers. The wastewater wish drains through the filter packing is accumulated into an equalizer and recirculated to the top of the filter.

Common filter packing materials include sawdust,[2][3] wood chips, bark, peat, straw and sawdust for organic packing, and gravel, quartz sand, river bed gravel, mud balls, glass balls, ceramsite and coal for inert packing. Filter packings specific surface area and porosity of filter packing materials has also been reported to impact treatment performance.[4] Materials with low granulometry, and large surface area, may be used to improve the performance of the vermifilter.

Process

Vermifilters provide an aerobic environment for microrganisms growth, as these are also called biofilm. Such microrganisms are stimulated by earthworms and grow according to earthrorm abundance. Microrganisms present are heterotrophic and autotrophic and, these last, are important in nitrification.

Earthworms are very important in the digestion of the solid organic particles present in wastewater.[5] They actively digest the solid particles and an equilibrium is reached whereby digestion matches the volume of solid waste influent. Variation in seasonal and environmental factors (temperature, humidity and insolation), hydraulic factors (hydraulic retention time, hydraulic loading rate and organic loading rate) and biologival factors (earthworms) can reduce treatment efficiency. There is some evidence that the wet environment facilitates digestion of solid waste by earthworms.[6]

The filtration process is immediate and takes place before dissolved oxygen would be required for organic decomposition of the solid waste. Vermifilters provide a similar level of liquid effluent treatment to a septic tank,[7] but in a shorter time because digestion of solids by worms takes place rapidly in the aerobic environment.[6] Solid material is reduced to wormcastings, with reductions of up to tenfold.[8] Since treated effluent is discharged almost immediately after entering the vermifilter, little dissolved oxygen is consumed by the wastewater through the filtration stage. However, oxygen demand is leached into the wastewater flow through the filter as earthworms digest retained solids,[9] but since they consume little oxygen amounts during their metabolism, low BOD5 concentrations are expected.

Types

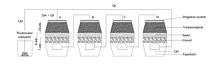

Vermifilters are typically systems with one filter packing chamber but several system could have two to four chambers as these are usually called sequential vermifilters.

The drainage within the vermifilter is provided by filter packing according to the hydraulic conductivity and permeability of each material that are present within the vermifilter. The filter packing has the dual purpose of retaining the solids present in effluent wastewater providing also a suitable habitat for sustaining a population of Epigenic earthworms. This population requires adequate moisture levels within the filter packing, but good drainage also. Most vermifilters are basically made as single tower systems or combined vermifiltration processes in the treatment of different types of wastewater. Even so, different level stages [10][11] can increase treatment efficiency as they systems provide excellent aerobic conditions for nitrification, increasing the removal rates for COD and NH4+.

Sizing and Design

In envirionental engineering and vermitechnology, the design parameters of vermifilters include stocking density of earthworms,[12] filter media composition,[13] Hydraulic loading rate,[14] Hydraulic retention time[3][15] and Organic loading rate. Hydraulic retention time and Hydraulic loading rate both affect treatment and effluent quality. Hydraulic retention time determines the actual time the wastewater is in contact with the filter and is proportional to the depth of the vermifilter witch may increase over time due to the accumulation of earthworm vermicastings. It depends on wastewater flow rate, vermifilter volume and type of material used.

In principle, within certain ranges, the longer the wastewater remains inside the filter, the greater will be the BOD5 and COD removal efficiency, but at the expenses of larger filter volumes. The main reason is that wastewater requires a certain contact time with the biofilm to allow for the adsorption, transformation, and reduction of contaminants.[16] Hydraulic loading rate is an essential parameter in the design stage of all filters and determines the volume and amount of wastewater that a vermifilter can reasonably treat in a given time. For a given system, higher Hydraulic loading rates values will cause Hydraulic retention time to decrease and therefore reduce treatment efficiency. Hydraulic loading rate may depend on parameters such as structure, effluent quality and filter packing bulk density, and method of effluent application.[17] Common Hydrailic retention time values in vermifiltration systems range from 1 to 3 h.[18] As for Hydraulic loading rates, the values commonly used have been between 0.2 m3 m−2 day−1,[19] 3.0 m3 m−2 day−1 [20] or 10-20 g L−1.[1] Organic loading rate is defined as the application of soluble and particulate organic matter (as BOD5) per unit area per unit time.[17][21]

Treatment efficiency is influenced by health, maturity and population abundance of earthworms. Abundance is a fundamental parameter for efficient running of vermifiltration.[22] Thus, to ensure an efficient treatment system, sufficient earthworm abundance is necessary. Different values are reported in literature usually in grams or number of individuals per volume of filter packing or surface area of filter packing. Common densities vary between 10 g L−1 and 40 g L−1 per filter packing material.[23][24]

It is proved that hight earthworm abundances and particular process conditions in the vermifilter, could decrease treatment efficiency, in particular BOD5, TSS and NH4+ removal. The main causes are related with the fact earthworms release organic matter into the filter and stimulate nitrogen mineralization. In fact, dissolution of earthworm castings may have substances witch may have contributed to higher BOD5 concentration.[25]

Maintenance

A vermifilter has low mechanic and manual maintenance, and normally doesn't require any energy to work. Depending of wastewater quality requirements, recirculation could be avoided, and pumping shouldn't be needed.

Wastewater flow rate from septic to vermifilter is normally made by gravity so no pumping is required. Depending on each case, but usually in very particular situations, a septic tank could be avoided, so the solids are first trapped into the vermifilter. This could avoid the formation of sludge in the septic tank and no energy consumption for pumping, but it will take a more demanding maintenance to clean the pipes or sprinklers. An annual application of dry organic materials on the top of the vermifilter is required. Normally, it doesn't take more than 5 minutes to apply 1 cm of material, the amount required during each maintenance task. The volume of vermicast increases only slowly and occasionally vermicompost needs to be removed from the vermifilter. This task is easily made by removing the first centimeters of soil formed during the process. The vermicompost is collected and dried suspending temporarily part of the wastewater flow.

Environmental benefits

Since treated effluent is discharged almost immediately after entering the vermifilter, little dissolved oxygen is consumed by the wastewater through the filtration stage. However, oxygen demand is leached into the wastewater flow through the filter as earthworms digest retained solids.[9] This oxygen demand can be removed with secondary vermifilter reactors.[9]

See also

References

- 1 2 Lourenço and Nunes, submitted. Lourenço, N., Nunes, L.M., Submited. Optimization of a vermifiltration process for treating urban wastewater. Ecological Engineering.

- ↑ Arora, S., Rajpal, A., Kumar, T., Bhargava, R., Kazmi, A.A., 2014. Pathogen removal during wastewater treatment by vermifiltration. Environ. Technol. 35, 2493–2499.

- 1 2 Arora, S., Rajpal, A., Kazmi, A.A., 2016. Antimicrobial Activity of Bacterial Community for Removal of Pathogens during Vermifiltration. J. Environ. Eng. 142 (5).

- ↑ Dahab, M.F. 1982 Effect of media design on the performance of fixed-bed anaerobic filters. Water Science & Technology, 15, 369–383.

- ↑ Rajiv K. Sinha, Gokul Bharambe, Uday Chaudhari. Sewage treatment by vermifiltration with synchronous treatment of sludge by earthworms: a low-cost sustainable technology over conventional systems with potential for decentralization, Environmentalist, 2008 28:409-420.

- 1 2 C. Furlong, W. T. Gibson, M. R. Templeton, M. Taillade, F. Kassam, G. Crabb, R. Goodsell, J. McQuilkin, A. Oak, G. Thakar, M. Kodgire, R. Patankar. The development of an onsite sanitation system based on vermifiltration: the "Tiger Toilet", Journal of Water, Sanitation and Hygiene for Development, January 2015.

- ↑ A.S. Molla , P. O. Antwi , R.A. Buamah , H.M. Essandoh , E. Awuah The Potential of Subsurface Infiltration for the Treatment of Biofil Toilet Technology Effluent, Management Studies, December 2015.

- ↑ C. Furlong, M.R. Templeton, W.T. Gibson and will be converted into vermicompost. Processing of human faeces by wet vermifiltration for improved on-site sanitation Processing of human faeces by wet vermifiltration for improved on-site sanitation, Journal of Water, Sanitation and Hygiene for Development 4(2):231, June 2014.

- 1 2 3 Taylor, M. Clarke, W. P., Greenfield, P. F. The treatment of domestic wastewater using small-scale vermicompost filter beds, Journal of Ecological Engineering, December 2003 21: 197–203.

- ↑ Wang, L., Guo, F., Zheng, Z., Luo, X. & Zhang, J. 2011 Enhancement of rural domestic sewage treatment performance, and assessment of microbial community diversity and structure using tower vermifiltration. Bioresource Technology, 102, 9462–70.

- ↑ Tomar, P., Suthar, S. 2011 Urban wastewater treatment using vermi-biofiltration system. Desalination, 282, 95–103.

- ↑ Sinha, R.K., Bharambe, G., Chaudhari, U., 2008. Sewage treatment by vermifiltration with synchronous treatment of sludge by earthworms: a low-cost sustainable technology over conventional systems with potential for decentralization. Environmentalist, 28(4), 409–420.

- ↑ Cardoso-Vigueros, L., Ramírez-Camperos, E., Garzón-Zúñiga, M., 2013. Evaluation of a pilot vermifilter for the treatment of wastewater. Ingeniería Agrícola y Biosistemas, 5(2), 33–44.

- ↑ Kumar, T., Bhargava, R., Prasad, K.S.H., Pruthi, V., 2015. Evaluation of vermifiltration process using natural ingredients for effective wastewater treatment. Ecol. Eng. 75, 370–377.

- ↑ Arora, S., Rajpal, A., Kumar, T., Bhargava, R., Kazmi, A.A., 2014. A comparative study for pathogen removal using different filter media during vermifiltration. Water Sci. Technol. 70, 996–1003.

- ↑ Hughes, R.J., Nair, J., Ho, G., 2008. The toxicity of ammonia/ammonium to the vermifiltration wastewater treatment process. Water Sci. Technol. 58, 1215–20.

- 1 2 Siegrist, R.L., 1987. Soil Clogging During Subsurface Wastewater Infiltration as Affected by Effluent Composition and Loading Rate. J. Environ. Qual. 16(2): 181-187.

- ↑ Sinha, R.K., Bharambe, G., Chaudhari, U., 2008. Sewage treatment by vermifiltration with synchronous treatment of sludge by earthworms: a low-cost sustainable technology over conventional systems with potential for decentralization. Environmentalist 28, 409–420.

- ↑ Li, Y.S., Xiao, Y.Q., Qiu, J.P., Dai, Y.Q., Robin, P., 2009. Continuous village sewage treatment by vermifiltration and activated sludge process. Water Sci. Technol. 60(11), 3001–10.

- ↑ Manyuchi, M.M., Kadzungura, L., Boka, S., 2013. Vermifiltration of Sewage Wastewater for Potential Use in Irrigation Purposes Using Eisenia fetida Earthworms, 538–542.

- ↑ Otis, R.J., 2001. Boundary Design: A Strategy for Subsurface Wastewater Infiltration System Design and Rehabilitation. On-Site Wastewater Treatment Procedures: Proceedings of the Ninth National Symposium on Individual and Small Community Sewage Systems. ASAE. St. Joseph MI. p 245-260.

- ↑ Li, Y.S., Robin, P., Cluzeau, D., Bouché, M., Qiu, J.P., Laplanche, A., Hassouna, M., Morand, P., Dappelo, C., Callarec, J., 2008. Vermifiltration as a stage in reuse of swine wastewater: Monitoring methodology on an experimental farm. Ecol. Eng. 32, 301–309.

- ↑ Tomar, P., Suthar, S., 2011. Urban wastewater treatment using vermi-biofiltration system. Desalination 282, 95–103.

- ↑ Zhao, L., Wang, Y., Yang, J., Xing, M., Li, X., Yi, D., Deng, D., 2010. Earthworm-microorganism interactions: a strategy to stabilize domestic wastewater sludge. Water Res. 44(8), 2572–82.

- ↑ Lourenço, N., Nunes, L.M., Submited. Optimization of a vermifiltration process for treating urban wastewater. Ecological Engineering.